2023-06-30 05:43:11

3D Printer What exactly is the G code that appears when 3d printing?

3D PRINTING- How to interpret G-CODE?

3D printing

The rise of 3D printing technology can be traced back to the 1980s, but it has only gained widespread application and attention in recent years. Currently, it is widely used in the following industries:

Manufacturing: Manufacturers can simplify production processes, reduce material waste, and accelerate product development cycles through 3D printing technology.

Healthcare: It can be used to print simulated organs and tissue models for surgical simulation and practice by doctors. Additionally, 3D printing technology can be utilized for personalized manufacturing of medical devices, prosthetics, and orthopedic equipment.

Construction: By using 3D printing technology, construction models, components, and structural elements can be printed, resulting in improved construction efficiency, reduced material waste, and the realization of more complex designs.

Aerospace: The aerospace industry requires highly complex and precise components, and 3D printing technology offers the capability for rapid prototyping and customized production. It can also reduce component weight and enhance overall performance.

Automotive: Automotive manufacturers can leverage 3D printing technology for accelerated prototype development, customized parts, and improved product design. This helps improve manufacturing efficiency, reduce costs, and drive innovation.

Art and Design: Artists and designers use 3D printing technology to create unique artworks and decorations. They can achieve design concepts that were previously difficult to realize by printing complex structures and shapes.

With technological advancements and cost reduction, it is expected that 3D printing technology will play a role in more industries, bringing forth greater innovation and possibilities.

What G-code means?

G-code is an industry-standard programming language used in computer-aided manufacturing (CAM) and CNC machining. In this context, it refers to the code used to control the coordinates and the amount of filament extrusion for operating a 3D printer.

Most 3D data is saved in files called "STL" or "OBJ," but when it comes to printing with a 3D printer, the data needs to be converted into a format that can be printed using G-code.

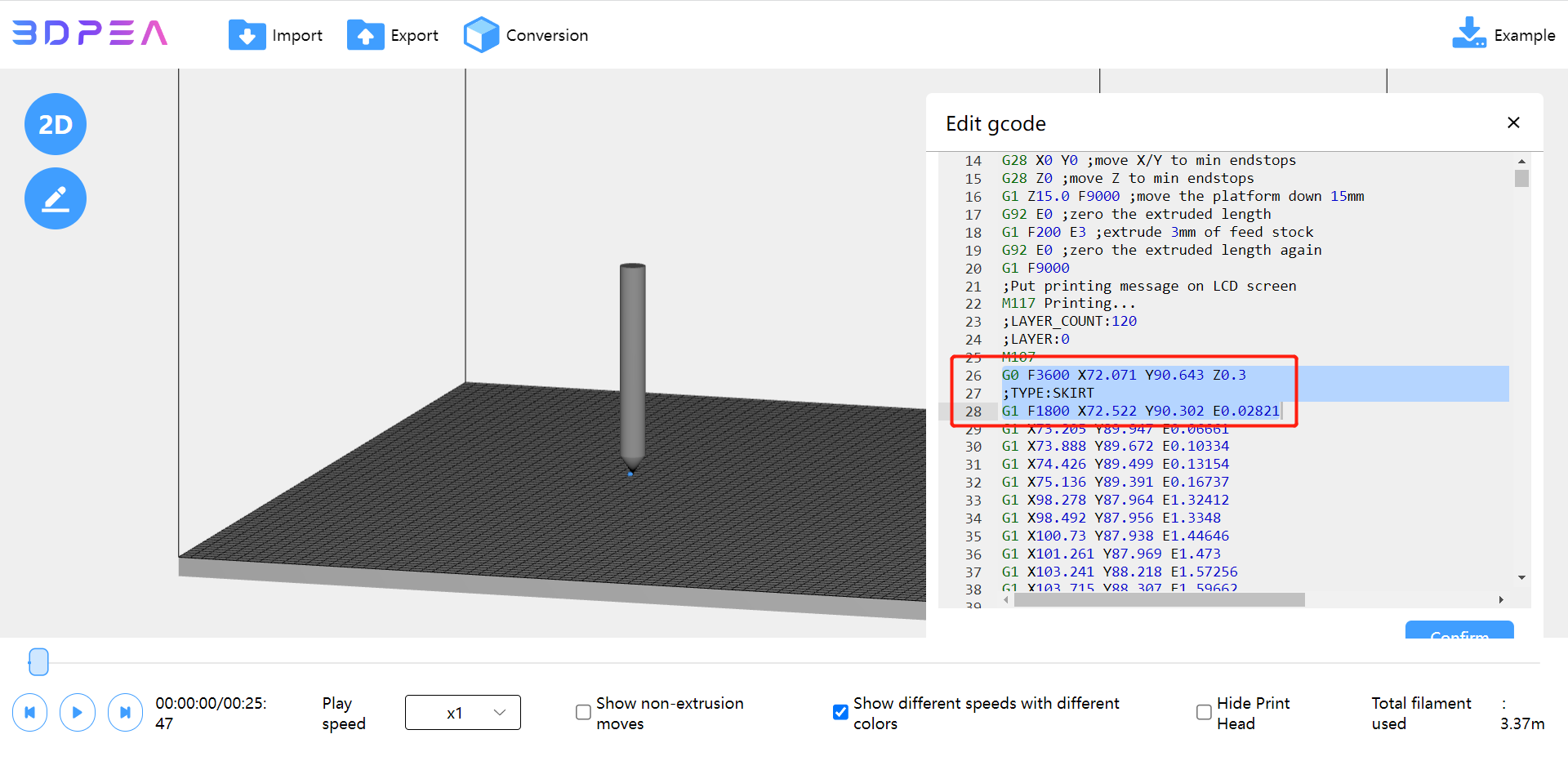

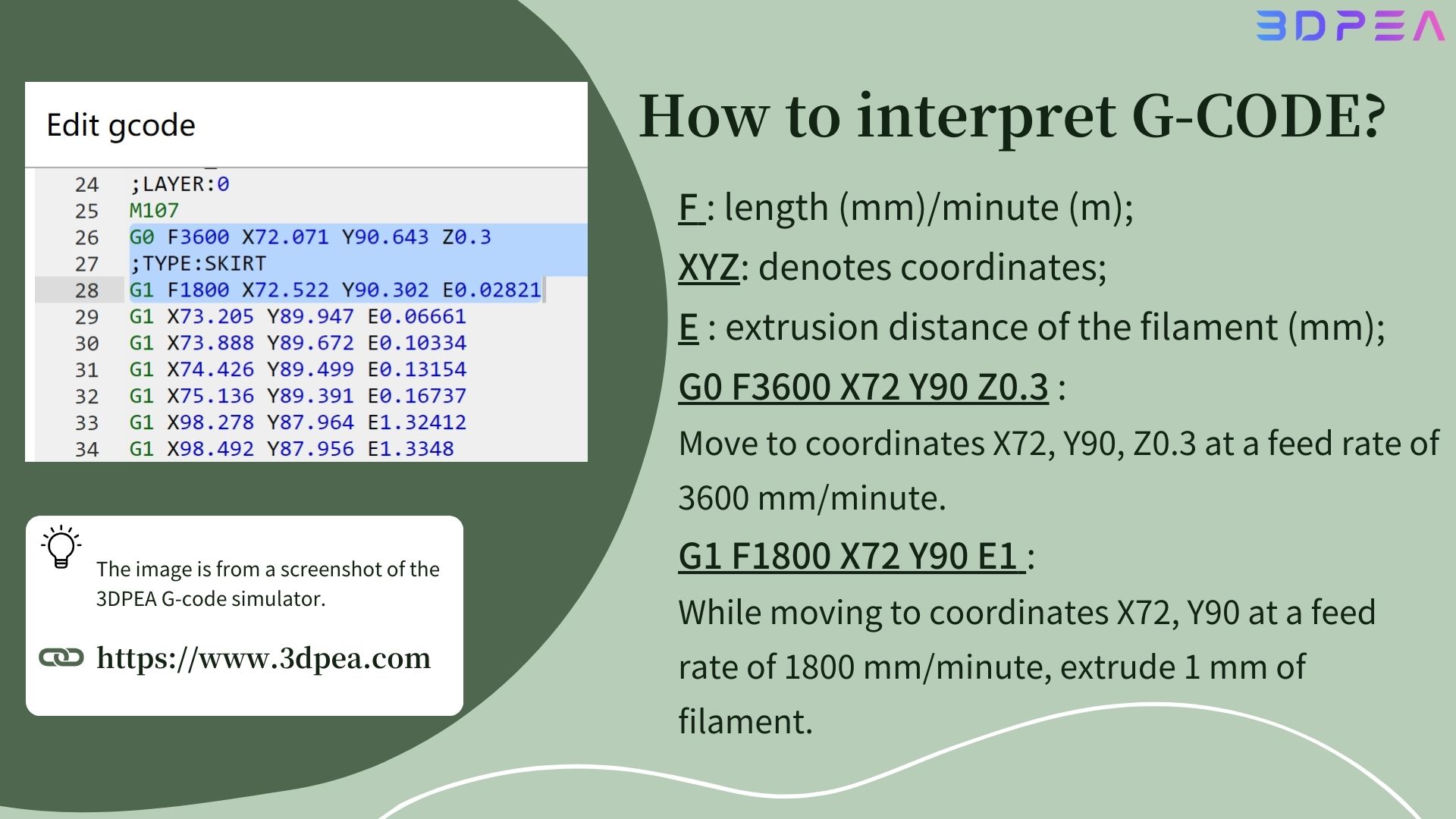

By using a 3DPEA G-code simulator, we can visualize the specific operation process of G-code during 3D printing and understand the meaning of each character and data. By examining the content of the G-code, it is possible to understand how a 3D printer operates.

What is G90 and G91?

Firstly, let's start by introducing two basic G-code commands. Just by knowing these two commands, you will be able to read most G-code instructions!

First, let's talk about G0. This command allows movement to a specified location without extruding filament. It is written as follows: G0 F(feedrate) X(x-coordinate) Y(y-coordinate) Z(z-coordinate).

Next is G01. In contrast, this command enables linear movement to the specified coordinates while extruding filament. It is written as follows: G1 F(feedrate) X(x-coordinate) Y(y-coordinate) Z(z-coordinate) E(extrusion distance).

Unlike G0, G1 requires specifying the extrusion distance at the end. In the provided example, when moving along the Y-axis by 10, it extrudes 1mm of filament.

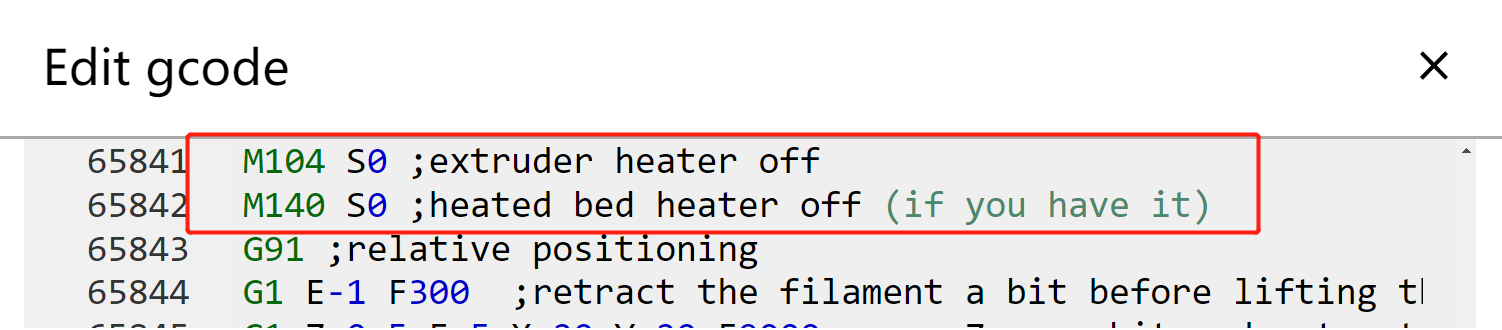

What is M104?

M104 is a temperature setting. By appending S followed by a numerical value, the table temperature can be raised to that specific temperature.

Now, let's move on to the topic of 3D printing a rectangular prism.

Before we proceed with the following description, there's a small point to note. The value of filament extrusion from the extruder accumulates unless it is reset.

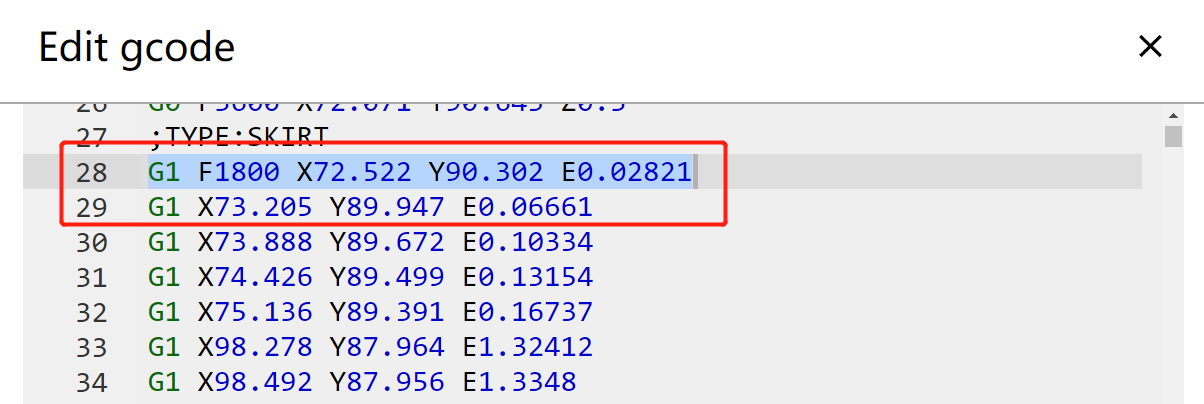

Please refer to lines 28 and 29. In line 28, 2821mm of filament is extruded. However, in line 29, only 3840mm of filament is extruded, calculated as follows:

6661mm - 2821mm = 3840mm

Above is a detailed introduction to G-code, which I hope will help you understand 3D printing. Log in to the 3DPEA G-code simulator to experience the entire process of 3D printing.